REACTOR

A chemical reactor is a device or system used to facilitate and control chemical reactions. It is designed to provide an environment where raw materials, also known as reactants, are transformed into desired products through chemical processes. Chemical reactors are used extensively in various industries, including chemical manufacturing, petrochemicals, pharmaceuticals, food production, and more.

Chemical reactors prepared of three types – designs & in configurations. each of one suited to specific type of reactions and process requirements.

Batch Reactors

These reactors are used for small-scale reactions where reactants are mixed in a vessel, allowed to react, and then the products are collected after the reaction is complete. Batch reactors are often used for research, development, and production of small quantities of specialty chemicals.

Continuous Stirred-Tank Reactors (CSTR)

In these reactors, reactants are continuously fed into a stirred tank, where the reaction takes place. The products are continuously withdrawn, maintaining a steady-state operation. CSTRs are commonly used in large-scale chemical manufacturing processes.

Plug Flow Reactor (PFR)

In a PFR, from time to time called continuous tubular reactor (CTR) one or more fluid reagents are pumped from side to side a pipe or tube. The chemical reaction proceeds as the reagents travel from side to side the PFR. In this kind of reactor, the varying reaction rate create a gradient with admiration to detachment traverse; at the inlet to the PFR the rate is extremely high, but as the concentrations of the reagents diminish and the attention of the invention increases the reaction rate slows.

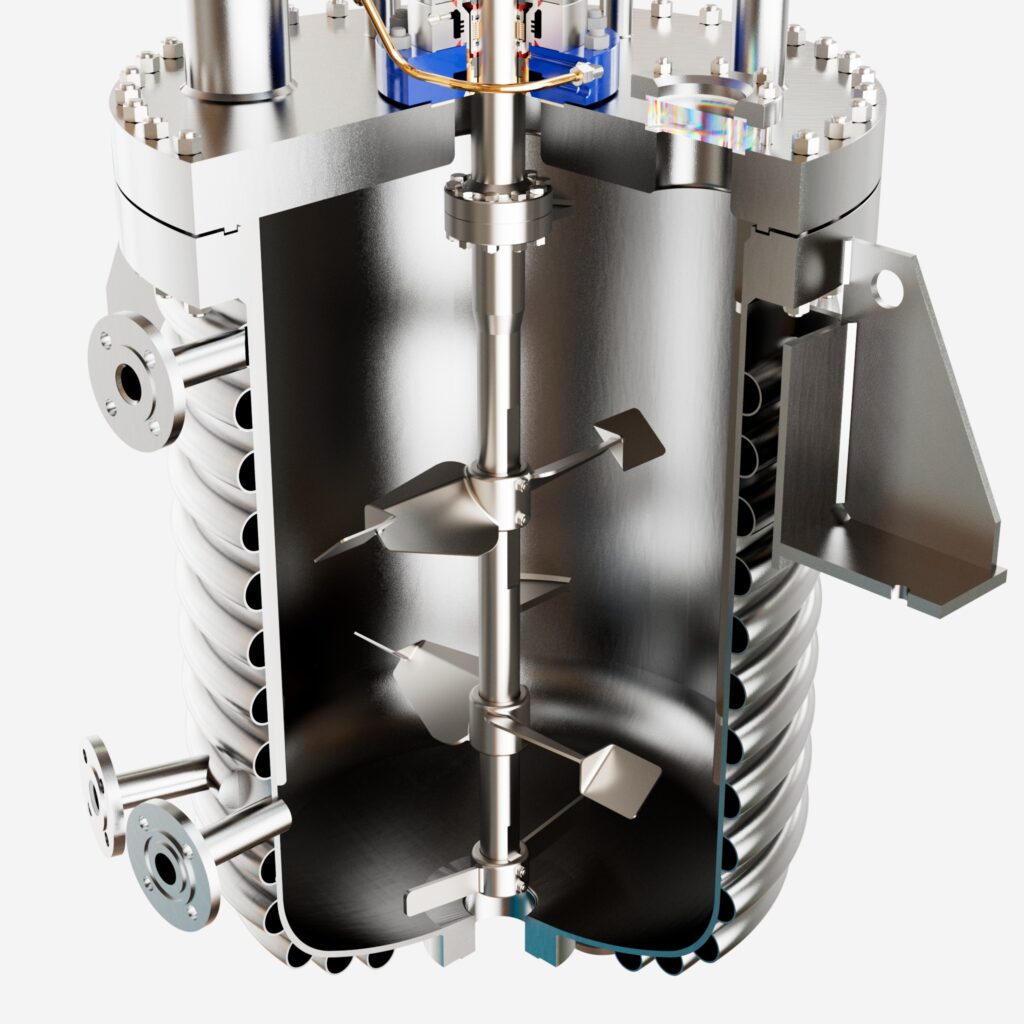

- Equipment Capacity : up to 50 m^3 (kl)

- Material of Construction : Stainless Steel 316L / 304 / 316 / 321, Mild Steel, Carbon Steel, Hastelloy, etc

- Protective Layers : Glass Lined, PTFE / PP / Halar Coating, Hard Chrome Plating, Custom Protective Chemical Coats, Etc.

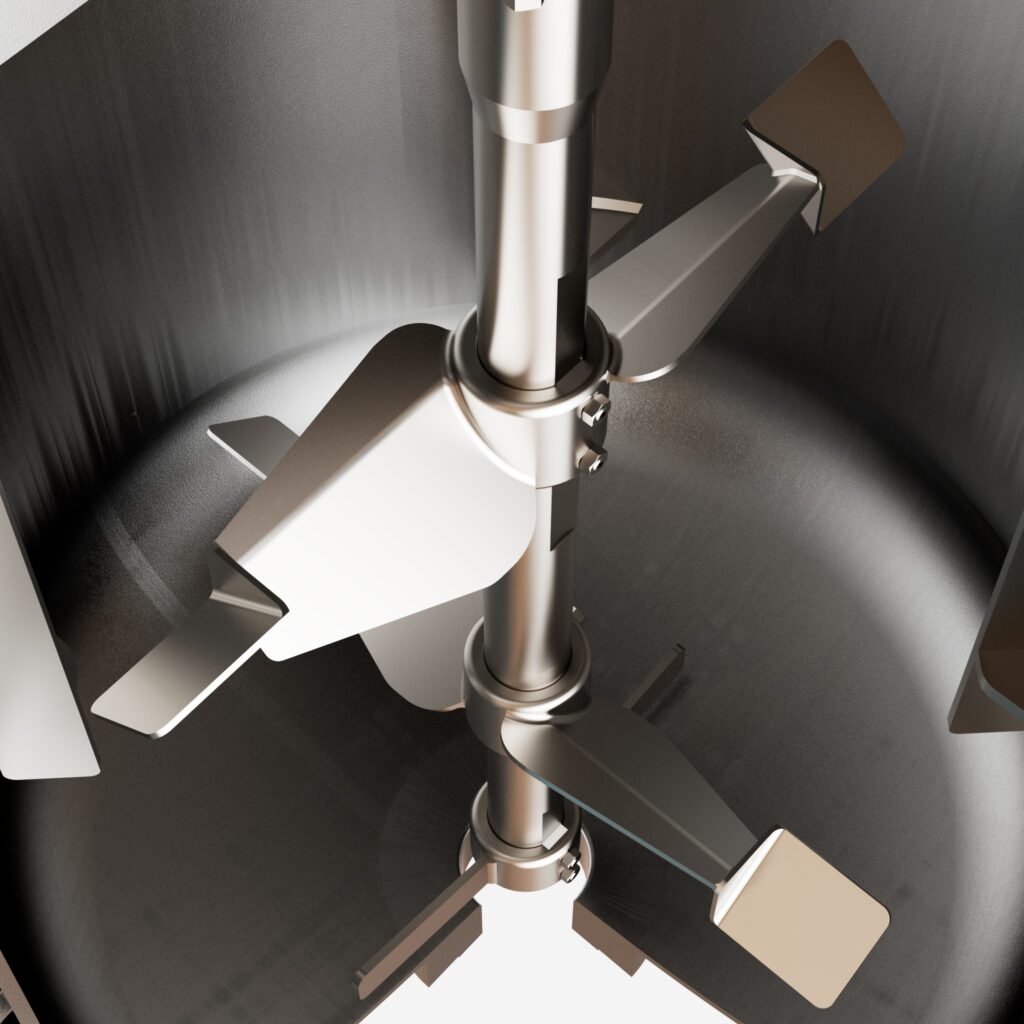

- Agitator / Mixing Mechanism : Type as required, upto 1000 RPM.

- Motor / Gearbox : Standard Make / Customized / as required.

- Jacket / Limpet Coil : Customized as per Requirement.

- Baffle Plates / Seals / Nozzles : as required.

- Surface Finish : Mirror Finish / Polished / Painted.

Application

- Chemical Manufacturing Industry

- Petrochemicals Industry

- Pharmaceuticals Industry

- Food & Beverage Industry

The choice of reactor type depends on factors such as reaction kinetics, temperature, pressure, safety considerations, desired product fields, and efficiency. Engineers and chemists carefully select and design the appropriate reactor for a given chemical process to ensure optimal conversion rates, selectivity, and yield while adhering to safety and environmental regulations.