PULVERIZERS

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steam-generating furnaces of coal power plants. Pulverizers are commonly used in the coal industry but can be suited for a variety of applications. The main purpose of these machines is to process materials and act as size reduction equipment. A pulverizer reduces materials like Limestone and gypsum at high speeds resulting in smaller particle sizes.

Typically, Pulverizers are sorted into three major groups:

Grinding Mills Crushers Impactors

Note that within these groups are many specific types of pulverizers, defined by their application,such as coal pulverisers, concrete pulverizers, food pulverizers, and plastic pulverizers.

- Grinding Mills : Grinding mills break down materials using friction, which they generate via grinding media. Any number of coarse materials may serve as grinding media, but some, such as brass, bronze, ceramics, flint, and non-sparking lead, are more common than others. The sub-types are as,

1. Ball Mill 2. Hammer Mill 3. Tube Mill

- Crushers : Crushers are used to crush large, dense materials like rock and stone, until it is dust or gravel. Usually, they are used to simplify the differentiation of materials or to reduce materials and/or prepare them for recycling or disposal. The most common type of crusher is the jaw crusher.

1. Jaw Crusher 2. Blake Crusher 3. Dodge Crusher 4. Universal Crusher

- Impactors : Impactors are quite like crushers, except that they reduce materials differently. Instead of crushing, which uses pressure generated by two opposing forces, they use impaction, a process that transmits force via collision. To carry out impaction, impactors, or impact crushers, contain the material to be crushed inside a cage, with which they facilitate collisions. As the material gets smaller, it falls out of openings on the bottom, side, or end of the cage. Along with the above common pulverizer types are those types that are less common, but more specialized, such as,

1. Gyratory crushers 2. Cone Crusher 3. MPS Mills 4. Bowl Mills

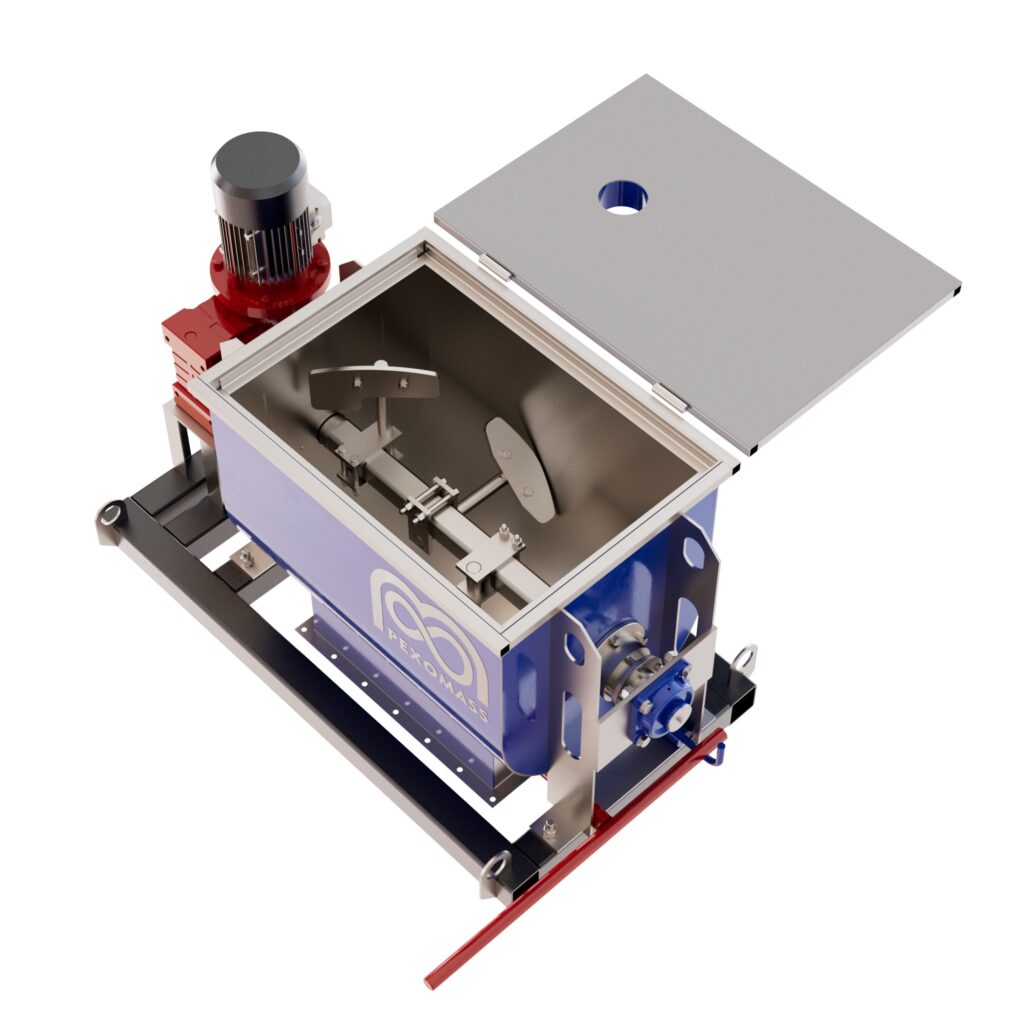

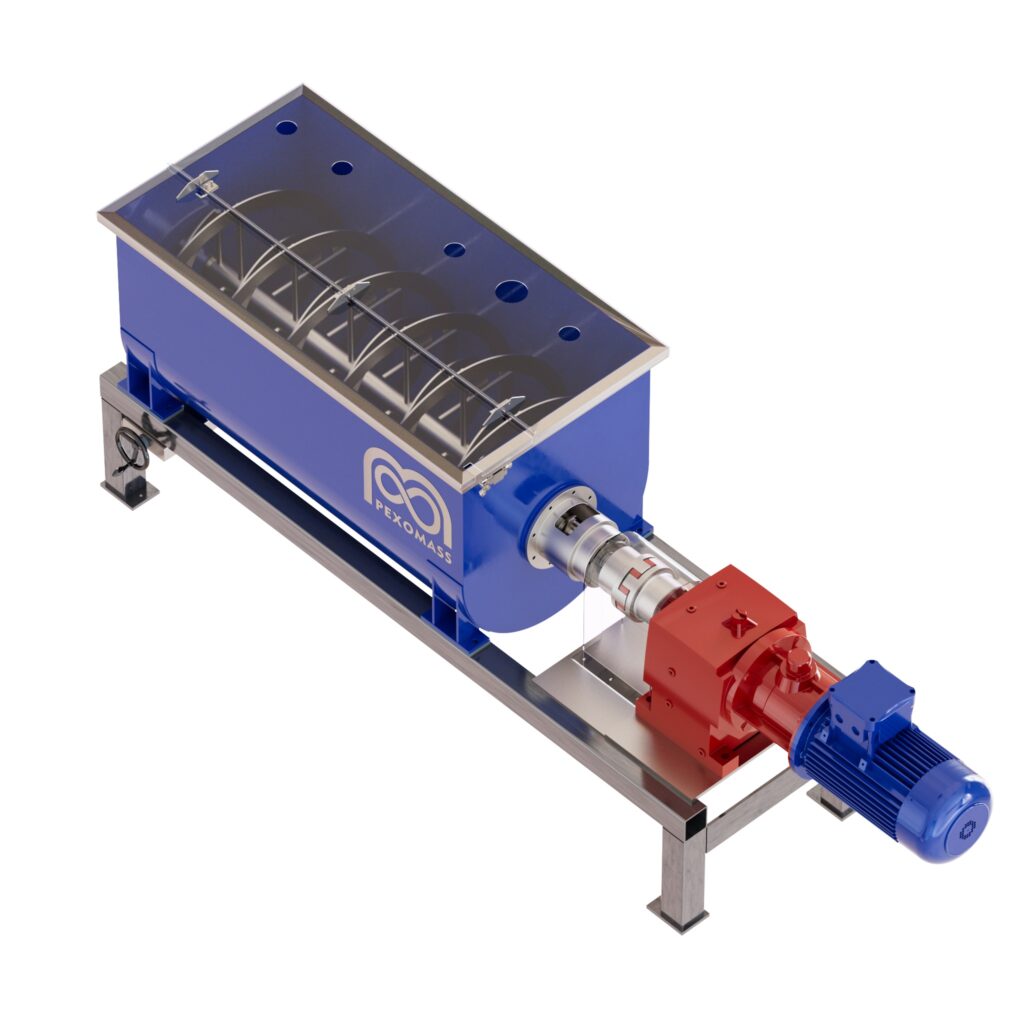

Pulverizer machines may have different components depending on their kind. However, in general, they work using entry feed, a rotating element (e.g. rotating cylinder), a crushing element (e.g. steel balls), and an exit feed. Some pulverizers also have temperature control and air flow components (air precleaner, air compressors, etc.) that help dry newly crushed material. To promote safety, they frequently feature accessories like automatic shut-off programming, shields, sensors, and guardrails.

When helping you select a pulverizer or when designing a custom pulverizer for you, pulveriser suppliers consider factors like feed quantity, the breaking behavior of the material you will be sending

through the feed, its initial texture (coarse, fine, etc.), its level of abrasion resistance, its initial hardness, its initial cleanliness (any contaminants it may carry), and the required finished texture and fineness of the material you are grinding. .

Based on these factors, pulverizer manufacturers can decide on the right pulverizer configuration for you, whether your pulverizer should run continuously or in batches, whether or not your pulverizer requires an airflow component, the right pulverizer speed, and what grinding tools are best for you.