CENTRIFUGE

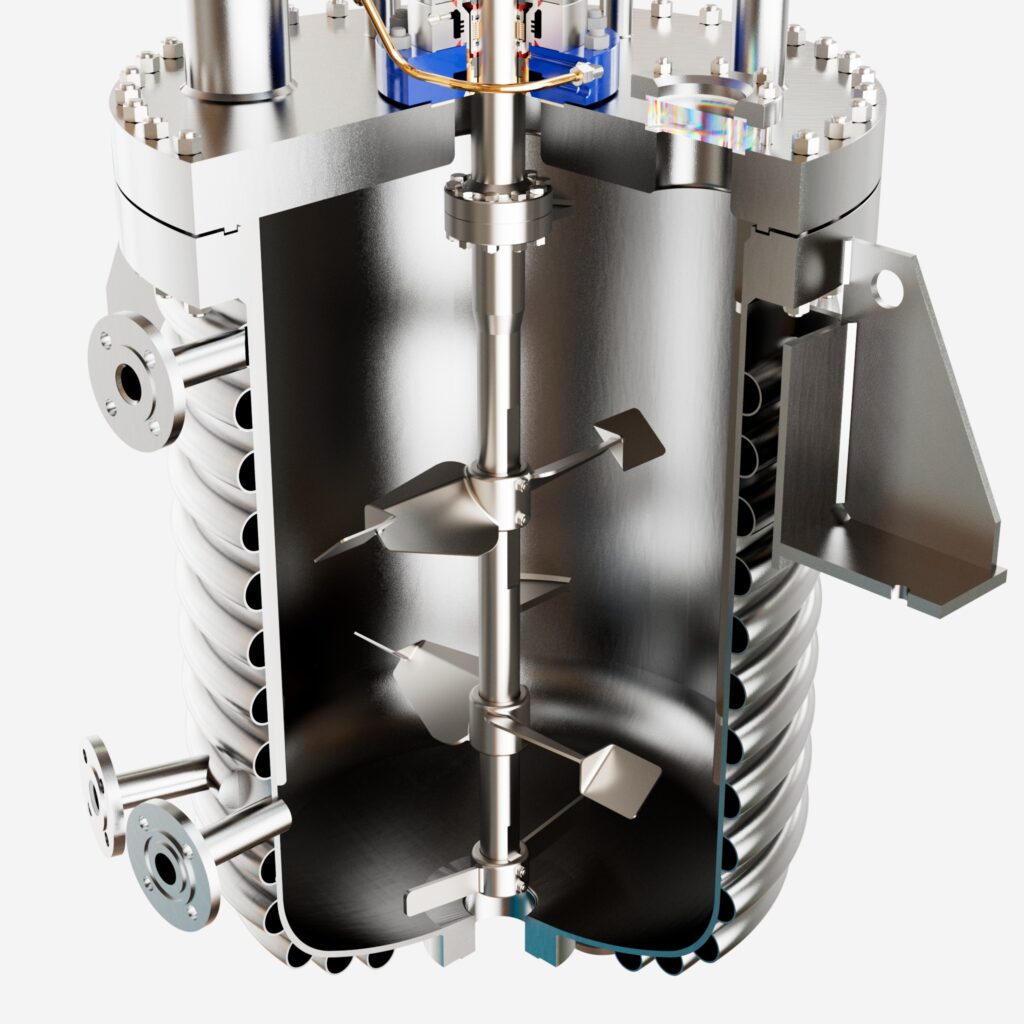

An industrial centrifuge is a mechanical device that uses centrifugal force (g-force) to separate substances or particles of different densities within a liquid or mixture. Industrial centrifuges offer a wide range of applications, such as separation, clarification, and filtration of various substances. These industrial centrifuges are widely used in various industries and applications, including beverage, dairy, bio-diesel, food processing, renewable resources, chemical, biotechnology, pharmaceutical, marine, energy, oil & gas, environmental, mining, and others. Industrial centrifuges are versatile machines designed to separate solids and liquids or separate different liquids based on their densities and other physical properties. Centrifuge equipment is used for the following key centrifuge applications:

- Solid-Liquid Separation: Industrial centrifuges excel at separating solid particles from liquid suspensions.

- Liquid-Liquid Separation: Industrial centrifuges are utilized to separate immiscible liquids, such as oil and water, or to separate different liquid components based on their specific gravities.

- Particle Size Classification: Industrial centrifuges can effectively classify particles based on their sizes.

- Solids Dewatering: In industries dealing with sludge or other solid wastes, industrial centrifuges provide efficient dewatering capabilities.

Major Factors Affecting Sedimentation and Separation

Viscosity, density (specific gravity), particle size and shape are all important factors to be considered in both gravity settling and centrifugal separation. Stokes Law provides a basic formula for predetermining the theoretical rate of sedimentation under the force of one gravity. It states that a particle moving through viscous liquid attains a constant velocity or sedimentation rate. The sedimentation rate can be very slow for particles whose density is close to that of the liquid, for particles whose diameter is small, or where the viscosity is high.

The equation for Stokes’s Law of Sedimentation

Vg = d² (Pp – P1) / 18n x G

where:

Vg = Gravitational Settling Velocity (m/s)

d = Particle Diameter (m)

Pₚ = Particle Density (kg/m)³

P₁ = Liquid Density (kg/m)³

G = Gravitational Acceleration (kg/ms)

n = viscosity of the liquid (m/s)²

Gravity sedimentation relies on the force of gravity to separate particles based on their settling rates. This method of separation is slow compared to centrifugation and may require longer settling periods to achieve the desired separation. High-density minerals settle more rapidly than low-density minerals. Lower temperatures will increase viscosity, decreasing the fall velocity. The particle will be initially accelerated due to gravity, but eventually, the gravitational and drag forces reach an equilibrium, resulting in constant “terminal fall velocity.”