DRYERS

An industrial dryer is a high powered complex device designed to remove moisture from machinery products, materials, food products, and mixtures. They are large rugged durable industrial pieces of equipment capable of drying high volumes of product efficiently with exceptional precision & control. Drying can be defined as the vaporization of absorbed moisture from wet materials. It is a heat and mass transfer process that is completed using a variety of mechanisms. The basis of the process is the transfer of heat from the material to be dried, which causes the absorbed water to vaporize that is transferred to and carried by the surrounding air or inert gas.

Drying can be defined as the vaporization of absorbed moisture from wet materials. It is a heat and mass transfer process that is completed using a variety of mechanisms. The basis of the process is the transfer of heat from the material to be dried, which causes the absorbed water to vaporize that is transferred to and carried by the surrounding air or inert gas.

During the drying process, the humidity or moisture content of the surrounding air increases. The weight of the dried material decreases while the moisture free weight is constant. Some of the purposes of drying are:

- The prevent of the growth of bacteria, molds, and other microbes on food and pharmaceutical products.

- To protect materials from rust and corrosion

- To improve and maintain the positive properties of a material

- To prepare materials for further processing, storage, handling, and transportation

- To enhance functionality, usability, and the value of a product

- Tunnel Dryers

- Fluidized Bed Dryers

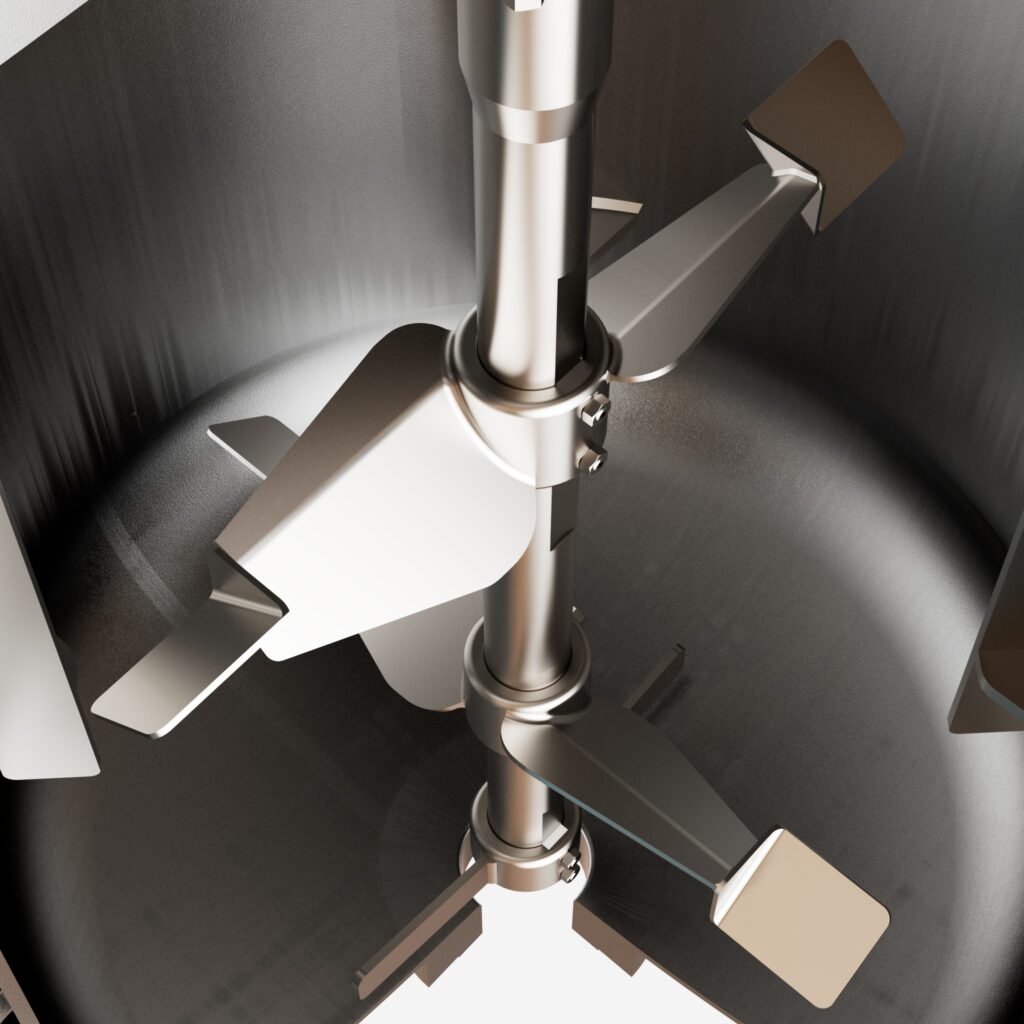

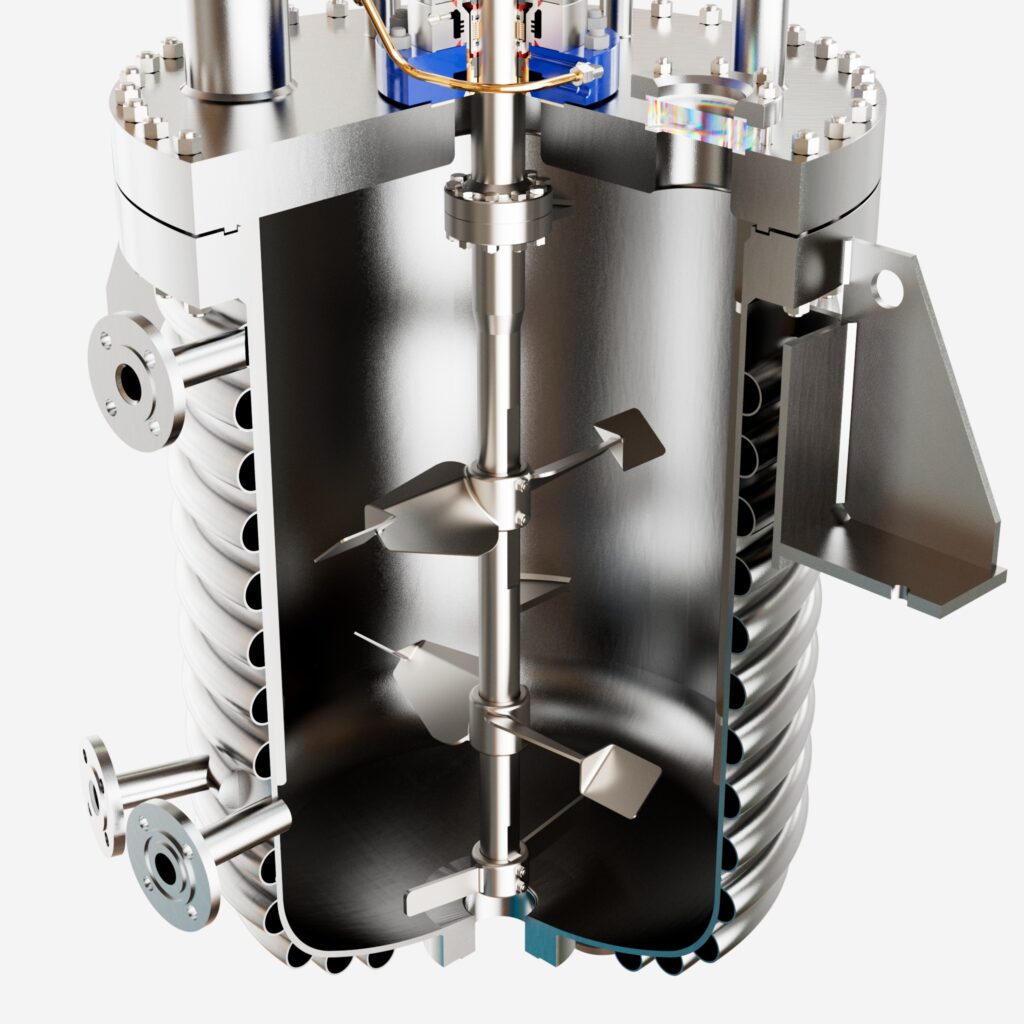

- Agitated Vacuum Dryers

- Disc Dryers

- Spray Dryers

- Flash Dryers

- Tray Dryers

- Vacumm Dryers

- Freeze Dryers

- Pan Dryers

- Bin Dryers