HEAT EXCHANGER / CONDENSERS

A Heat Exchanger or condenser is a device used to convert a vapour or gaseous substance into a liquid state through the process of condensation. It is commonly used in various industrial and scientific applications, particularly in heat exchange systems and processes involving vaporization and cooling. Condensers are crucial components in systems where the conversion of vapour to liquid is necessary for efficient operation or further processing.

The basic principle of a condenser involves the removal of heat from a vapour, causing it to lose thermal energy and transition into a liquid state. This process involves transferring the heat from the vapour to a cooling medium, typically air or a circulating fluid like water.

There are different types of condensers used in various applications:

Surface Type: This type of condenser is commonly used in steam power plants and other industrial processes. It consists of a shell-and-tube arrangement where steam is condensed on the outer surface of the tubes, and cooling water circulates inside the tubes. The steam releases heat to the cooling water, resulting in condensation and the formation of liquid water.

Shell and Tube Type: Similar to the surface condenser, this type uses a shell-and-tube configuration, but it’s not limited to steam applications. It’s used for various fluids and gases that need to be condensed. The vapour flows through the tubes, and the cooling medium (usually water) surrounds the tubes in the shell.

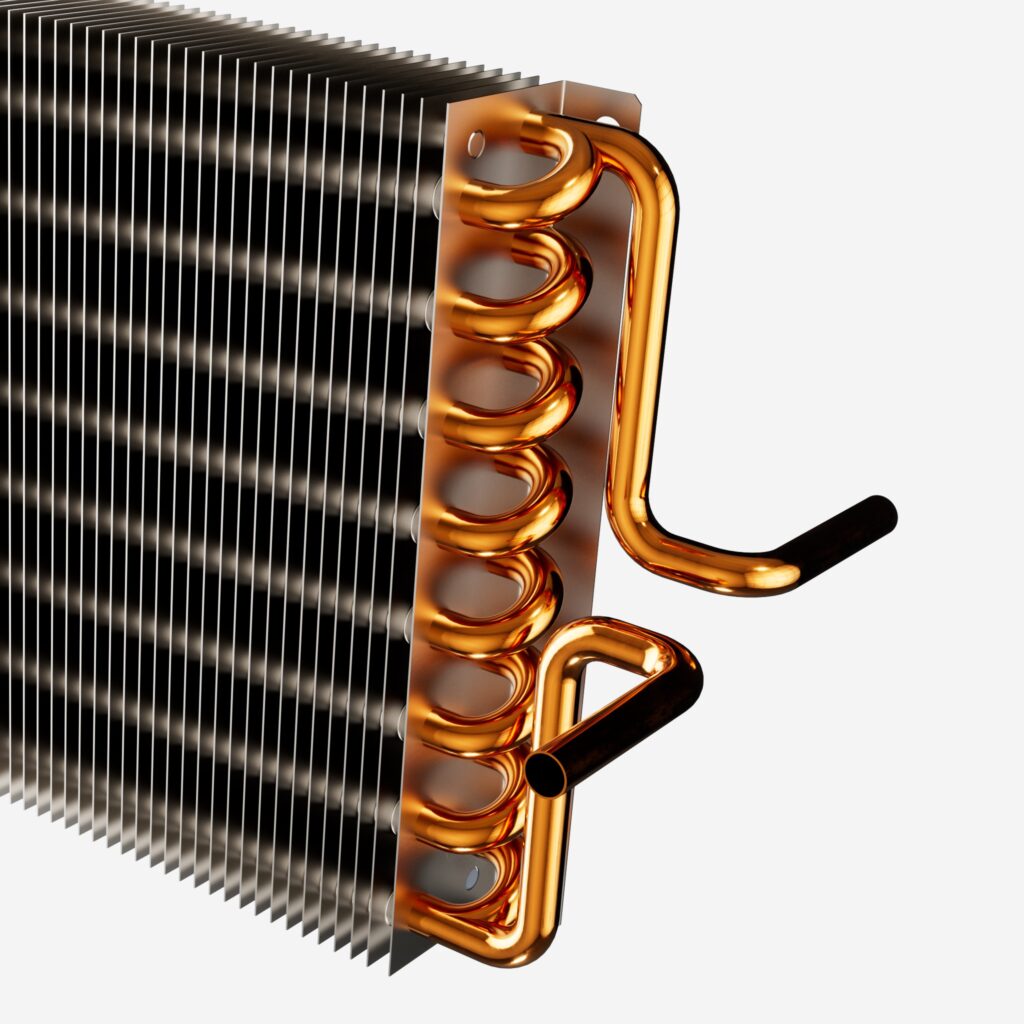

Air-Cooled Type: In situations where water availability is limited or costly, air-cooled condensersare used. These condensers use air as the cooling medium. Fins and tubes are designed to enhance heat transfer from the vapour to the surrounding air.

Evaporative Type: This type of condenser combines the condensation process with evaporative cooling. It’s commonly used in refrigeration systems and industrial processes. The hot vapour is condensed by direct contact with a spray of water, which then evaporates removing heat and enhancing the condensation process.

Jacketed Type: In laboratory settings, a jacketed condenser is often used for distillation and reflux processes. It consists of a glass tube surrounded by a water jacket. Vapour rise through the central tube, and cooling water in the jacket causes condensation.

Condensers are used in a wide range of applications including:

Steam power plants: To condense steam back into water after it has passed through the turbine.

Refrigeration systems: To liquefy refrigerant gases for efficient cooling.

Chemical processing: To recover volatile solvents or cool reaction products.

Distillation: To condense vaporized liquids back into a liquid state during distillation processes.

Air conditioning: To remove heat from the air by condensing refrigerant gases